Multi-Phase Separators

Multi-Phase separators internals are used downstream of the wellhead separator for treatment of the Crude oil and separation of the gas fraction, produced water and solids prior to further processing.

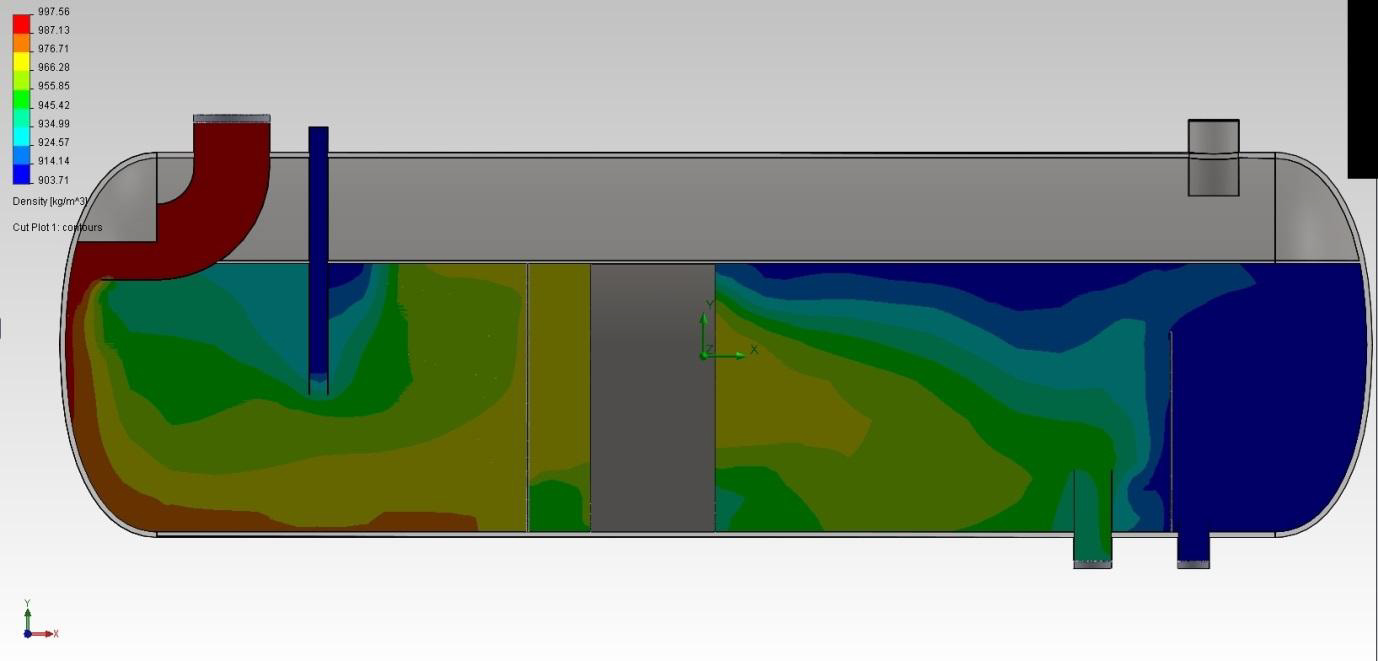

By using Pemtec separators internals: inlet devices, coalescing baffles, plate packs, demisters etc… a suitable solution can be defined to meet the various separation requirements. Detailed analysis and computational fluid dynamics (CFD) can be used to ensure client requirements are met.

The inlet internals of the separator are designed to achieve two primary roles:

Efficient release of the gas fraction from the liquid phase and

Effective flow distribution in the primary section of the separator

Enhanced Separation

After that initial gas-liquid separation, the next section of the separators internals is designed to enhance the natural separation of oil, water and solids. This is achieved by the use of baffle plates and coalescer plate packs.

The Produced Water is drained from the bottom of the vessel and sent for further treatment per operator requirements.

Solids are removed from the bottom of the separator with our Sand Fluidising Cyclones before sand washing and disposal.

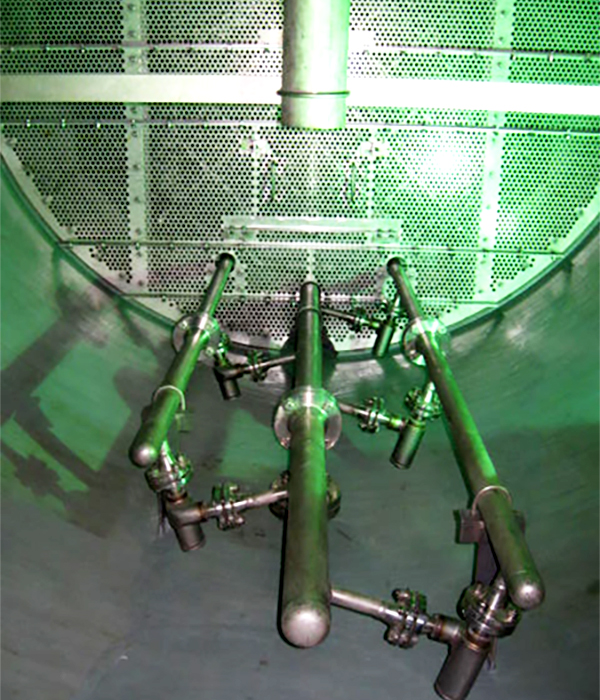

Sand Fluidisation Internals

As a more efficient alternative to Sand Jetting, the Pemtec Sand Fluidisation internals allows for on-line solids fluidization and transport of solids which have settled to the bottom of vessels. This device has no moving parts; it uses a motive fluid to fluidize solids in a controlled manner within a defined region of a vessel.

Providing good floor coverage each unit generates a high solids slurry for easy sand removal with optimal water usage.

The Sand Fluidisation internals are equally effective installed in new vessels or retrofitted into existing facilities.

Discover The Future

Smart designs for removing oil and suspended solids from produced water